Mark Post, a Dutch scientist, introduced the world’s first cultivated burger in 2013, a 5-ounce patty grown from cow muscle cells. This milestone demonstrated how meat could be produced without raising or slaughtering animals. Funded by Google co-founder Sergey Brin, the project cost £215,000 but laid the foundation for a growing industry focused on reducing the environmental impact of traditional farming. Post co-founded Mosa Meat in 2015 to make cultivated meat commercially viable, achieving significant cost reductions and technological advancements, such as removing the need for animal-based growth media. Today, cultivated meat is closer than ever to reaching consumers, promising a more sustainable way to meet global meat demand.

Mark Post's Cultivated Meat Journey: From Concept to Commercial Reality (2005-2025)

Mark Post's Path to Cultivated Meat

From Tissue Engineering to Cultivated Meat

Mark Post’s journey began in vascular physiology and tissue engineering, where he developed methods to grow blood vessels and skeletal muscle for transplantation. These techniques, initially aimed at helping patients in need of new blood vessels, eventually became the foundation for his groundbreaking work in producing meat without animals.

Post saw an opportunity to address pressing global challenges, particularly the environmental toll of traditional livestock farming. Livestock production is responsible for about 18% of all man-made greenhouse gas emissions, and nearly 70% of agricultural land is used for grazing. Meanwhile, with global meat demand expected to double by 2050, the strain on resources is only set to increase [2]. Reflecting on this shift in focus, Post remarked:

"Making hamburgers for a sustainability goal is just as valuable as making blood vessels for people." – Mark Post, Professor at Maastricht University

His reasoning was straightforward: if tissue engineering could create complex tissues for medical applications, why not use the same principles to grow muscle tissue for food? By employing scaffolds to provide physical anchor points and applying tension, Post was able to stimulate myosatellite cells to form muscle fibres. This innovative approach became the basis for his work in cultivated meat, which he advanced through the Dutch Cultivated Meat Project.

The Dutch Cultivated Meat Project

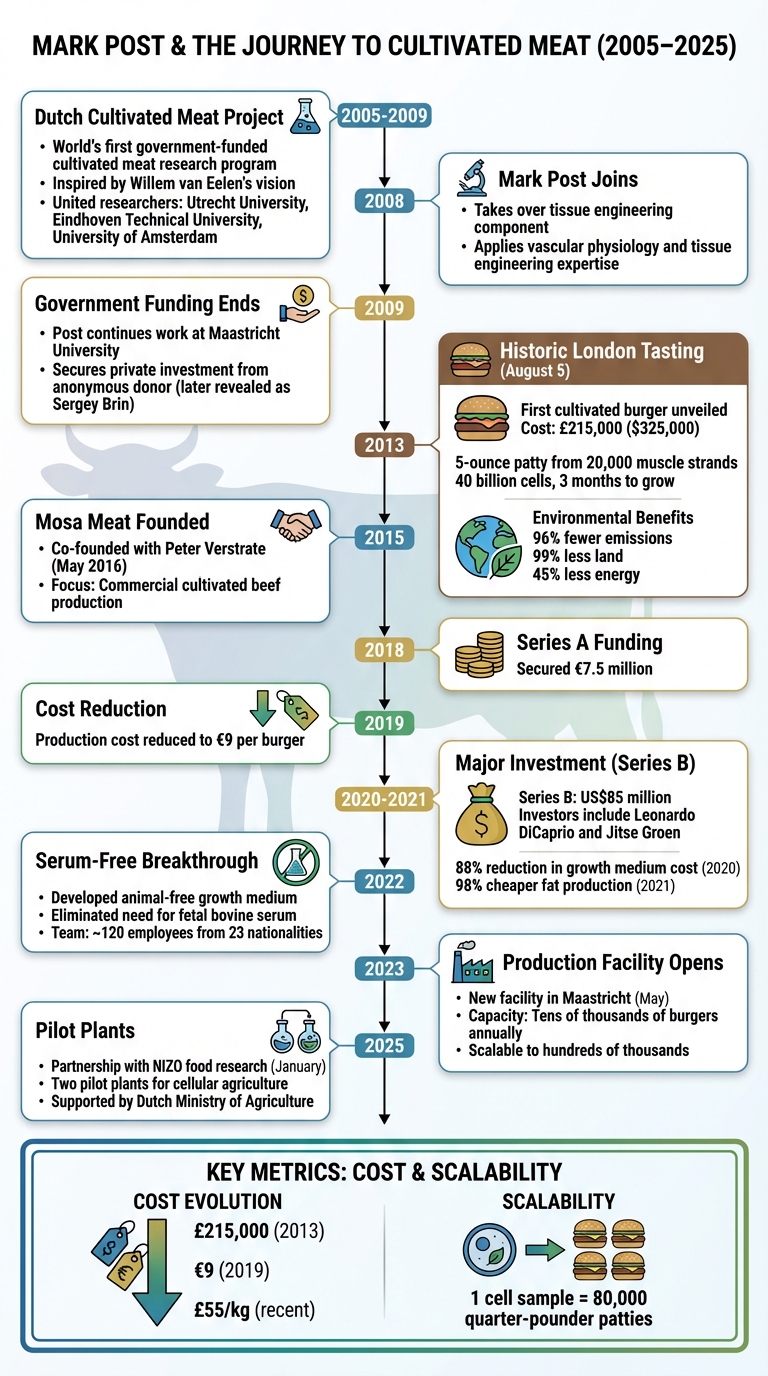

The transition from concept to reality took shape with the Dutch Cultivated Meat Project, a government-funded initiative that ran from 2005 to 2009. This was the world’s first government-supported research programme for cultivated meat, inspired by the vision of Willem van Eelen, a Dutch entrepreneur who held a patent on the idea and spent decades advocating for "no-kill meat" [7]. The project united researchers from Utrecht University, Eindhoven Technical University, and the University of Amsterdam.

Mark Post joined the project in 2008, taking over the tissue engineering component after Dr Carlijn Bouten stepped down. The project’s focus on stem cell biology, tissue engineering, and culture media provided the essential tools and knowledge that Post would later build upon.

When government funding ended in 2009, Post continued his work at Maastricht University. He secured private investment from an anonymous donor, later revealed to be Google co-founder Sergey Brin. This support enabled Post to create the world’s first cultivated meat burger, marking a major milestone in sustainable meat production. The Dutch Cultivated Meat Project was instrumental in setting the stage for this achievement, laying the groundwork for a new chapter in food innovation.

sbb-itb-c323ed3

Creating the First Cultivated Burger

Growing Meat from Cells: The Process

Mark Post's journey to creating the first cultivated burger started with a simple yet groundbreaking step: extracting myosatellite cells. These stem cells, which help repair muscle tissue, were taken from a cow's shoulder using a syringe [6]. Once extracted, the cells were placed in a growth medium containing fetal bovine serum and antibiotics, encouraging them to multiply and develop into muscle cells [3].

To replicate the structure of real muscle tissue, the team used a sugar-based scaffold with doughnut-shaped anchor points for support [3]. Inside a bioreactor, the muscle strands were "exercised" by applying tension between these anchor points, helping the tissue mature. As Post explained:

"The cells do the work on their own, we just provide the right conditions" [6].

In total, it took three months to grow the 20,000 individual muscle strands needed for a single five-ounce burger patty [3]. The finished product contained roughly 40 billion cells [3]. Since cultivated muscle tissue is naturally white, beet juice and saffron were added for colour, while breadcrumbs, caramel, and salt were used as binders and flavour enhancers [3,5]. This meticulous process, while innovative, posed several technical challenges.

Solving the Main Challenges

Creating the cultivated burger wasn’t without its obstacles. One of the biggest challenges was maintaining sterility, as nutrient-rich media are highly susceptible to contamination from bacteria and fungi, which grow faster than stem cells [10]. Muscle atrophy was another issue, which the team tackled by "exercising" the tissue in a bioreactor to keep it active and functional [3].

During the 2013 tasting event, the absence of fat tissue became apparent, impacting the burger's juiciness and flavour [3,6]. Another major hurdle was replacing fetal bovine serum with a fully animal-free growth medium. To address this, the team began exploring alternative options like algae-based media [8]. Overcoming these challenges not only proved the concept but also highlighted the importance of funding and further innovation.

Funding and Cost of Development

Funding played a critical role in bringing the cultivated burger to life. After Dutch government subsidies ended in 2009, the project faced an uncertain future [9]. The turning point came when Google co-founder Sergey Brin stepped in with financial support, allowing research at Maastricht University to continue. Brin even influenced the direction of the project, suggesting a focus on beef burgers over pork sausages [8].

The first cultivated burger came with a hefty price tag of around £215,000 (approximately €250,000 or $325,000) [5]. The high cost was due to the labour-intensive nature of cell culture, significant energy requirements, and the expense of the growth medium. However, as the technology advanced, production costs dropped significantly, reaching approximately €9 by 2019 [8]. This dramatic reduction signalled the potential for cultivated meat to become more accessible in the future.

The 2013 London Tasting Event

The Tasting Event: A Historic Moment

On 5th August 2013, history was made in London when the world’s first cultivated burger was cooked and tasted during a live news conference [11]. The 140-gram patty was prepared by chef Richard McGeown, who used sunflower oil and butter to fry it [11]. Two tasters - Austrian food researcher Hanni Ruetzler and American food writer Josh Schonwald - sampled the burger, offering their insights to an audience primarily made up of journalists [11].

The event was a media spectacle, complete with live-streaming video to capture the moment. Sergey Brin’s involvement added weight to the occasion, signalling to the tech and investment sectors that cultivated meat was a technology worth serious attention [4].

Both tasters praised the burger’s texture and bite. Ruetzler declared, "This is meat to me. It's not falling apart", while Schonwald highlighted its authentic mouthfeel, although he noted the absence of fat gave it a leaner quality [11]. The lack of fat was acknowledged as a current technical hurdle, impacting the juiciness of the product [11].

This milestone not only showcased the scientific achievement but also opened the door to rethinking the future of meat production.

Changing the Conversation About Meat

The success of the London tasting event reshaped perceptions of cultivated meat. It proved that meat could be grown from cells rather than sourced from slaughtered animals, marking a pivotal moment for the industry [4]. Reflecting on the achievement, Mark Post stated, "We proved it's possible" [12]. This demonstration of viable cultivated meat sparked discussions about ethical and sustainable approaches to meat production, aligning with Post’s broader goals.

During the event, an Oxford University study was cited, highlighting the environmental benefits of cultivated beef compared to traditional cattle farming. The study suggested it could generate 96% fewer greenhouse gas emissions, use 99% less land, and require 45% less energy compared to traditional cattle farming [11]. Sergey Brin encapsulated the significance of the technology, saying, "Sometimes a new technology comes along and it has the capability to transform how we view the world" [4].

This landmark moment didn’t just validate the science - it ignited a global conversation about sustainable meat production, setting the stage for cultivated meat to transition from the lab to the mainstream.

Mark Post's Impact: Founding Mosa Meat and Industry Growth

Mosa Meat: Advancing Commercial Cultivated Meat

The 2013 debut of the world's first lab-grown burger marked a shift from pure science to the challenge of engineering. In May 2016, Mark Post teamed up with food technologist Peter Verstrate to co-found Mosa Meat, aiming to transform their lab success into a viable commercial product[13]. The company zeroed in on cultivated beef, particularly ground beef, recognising that traditional cattle farming is one of the most resource-heavy forms of livestock production[13][14].

Initial funding came from Sergey Brin, but taking the technology to scale required much more investment. In 2018, Mosa Meat secured €7.5 million during its Series A funding round, followed by a significant US$85 million in Series B funding by early 2021. This round attracted prominent backers like Jitse Groen, CEO of Just Eat Takeaway, and actor Leonardo DiCaprio, who not only invested but also became an advisor[13].

DiCaprio highlighted the broader mission by saying:

"One of the most impactful ways to combat the climate crisis is to transform our food system. Mosa Meat and Aleph Farms offer new ways to satisfy the world's demand for beef."[13]

A major technical achievement came in 2022 when Mosa Meat developed a serum-free medium for muscle differentiation, removing the need for fetal bovine serum (FBS). This innovation tackled both ethical concerns and scalability issues, paving the way for further progress[13].

A Decade of Development

After their initial breakthrough, Mosa Meat focused on refining their processes to make production feasible on a larger scale. Back in 2013, creating the first burger required three lab technicians working for months to grow 20,000 muscle fibres[13]. Fast forward to 2020, and Mosa Meat had slashed the cost of its growth medium by 88%. By 2021, they had achieved a 65-fold cost reduction for their fat medium, making cultivated fat production 98% cheaper than earlier methods[13]. These cost reductions were key to overcoming early obstacles in commercialising the technology.

Reflecting on the journey, CEO Maarten Bosch said:

"We proved already in 2013 that we can make a hamburger. Now it's all about scaling up and getting the cost where it should be."[13]

In May 2023, Mosa Meat opened a new production facility in the Randwyck-Zuid business park in Maastricht. Limburg's governor Emile Roemer and Maastricht's mayor Annemarie Penn-te Strake inaugurated the facility, which has the capacity to produce tens of thousands of cultivated burgers annually, with room for scaling up to hundreds of thousands[13]. By February 2022, the company had grown to a team of around 120 employees from 23 different nationalities[13].

Taking another step towards full-scale commercialisation, Mosa Meat joined forces with NIZO food research in January 2025 to build two pilot plants for cellular agriculture. Supported by the Dutch Ministry of Agriculture and the National Growth Fund, this project aims to advance precision fermentation and cell cultivation technologies[13]. The company also began the approval process with the European Food Safety Agency (EFSA) in 2021. While cultivated meat is not yet on supermarket shelves, the groundwork for its commercial launch is well underway. Impressively, a single cell sample from a cow can yield up to 80,000 quarter-pounder patties, showcasing the potential scalability of this approach[14].

The Future of Cultivated Meat

Consumer Awareness and Education

Mark Post's 2013 demonstration proved that cultivated meat is scientifically possible, but making it a regular feature on dinner tables requires more than just innovation - it demands consumer understanding. Initially, many people reacted to the concept with scepticism, seeing it as unnatural. Changing this perception involves showing that cultivated meat is real beef, grown from cow cells and identical in taste and structure to traditional meat.

Educational tools play a key role here. They simplify the science behind how stem cells grow into muscle fibres and explain why the finished product is indistinguishable from conventional beef. These resources also spotlight the reduced environmental impact of cultivated meat. For example, cultivated beef uses 99% less land, just 4% of the water, and produces 96% fewer greenhouse gas emissions compared to traditional cattle farming[6].

As Mark Post explained:

"We are catering toward letting beef eaters eat beef in an environmentally friendly and ethical way."[3]

This approach isn’t about converting vegetarians - it’s about giving meat lovers a way to enjoy beef without the environmental toll. Post’s vision for ethical and sustainable beef relies on consumers understanding that cultivated meat is the same as conventional meat, just produced differently. Platforms like Cultivated Meat Shop help bridge the gap by offering educational content, previews of upcoming products, and waitlist options for those eager to try cultivated meat. These efforts aim to build an informed audience, ready to embrace the product when it hits the market. Early adopters from this group will play a key role in scaling production and normalising cultivated meat.

The Role of Early Adopters

Once consumers are educated, early adopters become essential in shaping the future of cultivated meat. Transitioning from a £215,000 prototype burger to an affordable supermarket product depends on these trailblazers. While initial funding from figures like Sergey Brin validated the technology, the next step relies on everyday consumers willing to try something new. Early adopters do more than just buy the product - they influence the market, provide feedback, and push companies to fine-tune their offerings before mass production.

Platforms like Cultivated Meat Shop foster this early engagement by keeping potential customers updated with product news and developments. This builds anticipation and readiness for the product's commercial launch. Mark Post’s vision of reducing global cattle numbers from 0.5 billion to just 30,000[9] hinges on these early supporters. By understanding and embracing cultivated meat, they pave the way for wider acceptance and help bring this innovative approach to the mainstream.

Dr. Mark Post looks back on 10 years in cultivated meat

Conclusion: Mark Post's Lasting Influence

Mark Post changed the way we think about meat production. On 5 August 2013, he unveiled a groundbreaking prototype - a burger grown entirely from cells. Though it came with a hefty price tag, this achievement proved that producing real beef without raising or slaughtering animals was no longer a futuristic dream but a scientific reality. This single event caught the attention of major investors, including Google co-founder Sergey Brin, and sparked an industry dedicated to ethical and sustainable meat alternatives.

By October 2015, Post took his vision further by co-founding Mosa Meat, a company focused on bringing cultivated meat to consumers. His ambition to reduce the global cattle population from 0.5 billion to just 30,000[1] has become a guiding objective for the entire field.

Post's work also reshaped discussions around sustainability in food production. His research demonstrated that cultivated beef could use 99% less land and emit 96% fewer greenhouse gases compared to traditional cattle farming[5]. These figures highlight the potential of cultivated meat to address some of the most pressing environmental challenges.

That first cultivated burger laid the groundwork for an entire industry. Post’s bold goal - “to replace the entirety of livestock production with cultured meat”[15] - continues to inspire innovation as production costs have plummeted from £215,000 to roughly £55 per kilogram[15].

For those eager to explore further, platforms like Cultivated Meat Shop offer resources and product insights inspired by Post’s pioneering efforts. His legacy isn’t just about creating the first lab-grown burger; it’s about proving that a better way of producing meat is not only possible but also necessary.

FAQs

Is Cultivated Meat safe to eat?

Cultivated meat has been deemed safe for consumption, thanks to extensive scientific research and thorough testing processes, including taste evaluations. Although it's a relatively new development, continuous studies are being conducted to maintain and verify its safety and quality standards.

Why was the first Cultivated Meat burger so expensive?

The hefty price tag of the first Cultivated Meat burger stemmed from a combination of factors: early-stage research, the need for specialised lab equipment, and the intricate challenge of growing muscle tissue in a controlled environment. Back then, this was an ambitious and resource-heavy endeavour.

When will Cultivated Meat be sold in the UK?

Cultivated meat, often referred to as lab-grown meat, is anticipated to make its debut in the UK within the next five years. Initially, it’s likely to be a premium product, available in select outlets. However, as demand grows and production costs decrease, it could eventually find its way onto supermarket shelves. This timeline aligns with projections shared by researchers like Prof Mark Post back in 2015.